Liner

MVG provides custom liner and manufacturing designs worldwide based on our patents, extensive research and development, and industry experience.

We provide all of the expertise to aid companies in manufacturing their own liner and also provide them with the raw materials to ensure the highest quality,

most competitively priced liner in the market. In addition, the MVG liner technology has been installed worldwide for more than 10 years,

including in many major cities in the U.S., such as Washington DC, Los Angeles, Baltimore, Salt Lake City, and more.

The Patent

MVG holds the US Patent US 9,248,605 B2. This application claims the benefit of U.S. Provisional Patent Application No. 61/098,326 to Rene Quitter filed on Sep. 19, 2008 and entitled INSERTION TUBE, which is incorporated by reference in its entirety for all purposes.

Test Results

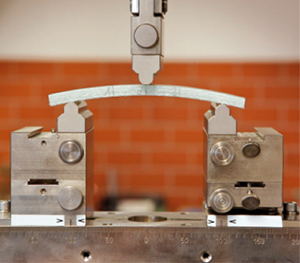

Flexural strength: 56,600 PSI

50 year flexural strength: 41,884 PSI (74% retention)

Flexural modulus: 1,910,000 PSI

50 year flexural modulus: 1,413,400 PSI (74% retention)

Tensile Strength: 79,580 PSI

Ring Stiffness: 10,583 N/m2

Characteristics

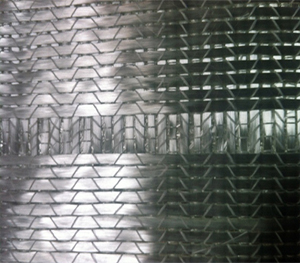

Glass reinforced: E-CR glass, unique weave for strongest results

UV Translucent Outerfoil: Proprietary and Patented

No Shrinkage: 0.02% loss

Thin Wall: 3mm to 14mm

Curing Speed: 7’ per minute (8”) 2’ per minute (48”)

Flow: Hazen-Williams C=150 Manning n=.009

Pressure applications: Optional

Non-VOC: Optional

Fireproof: Optional

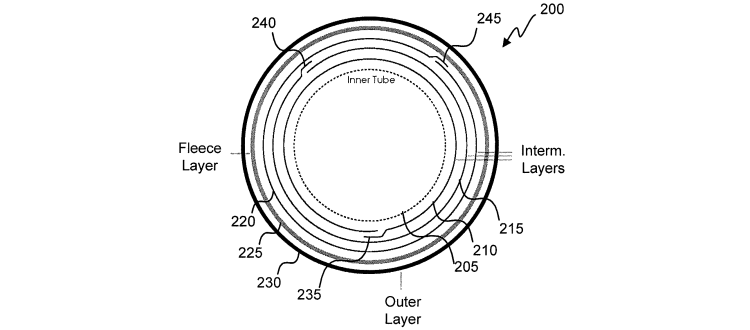

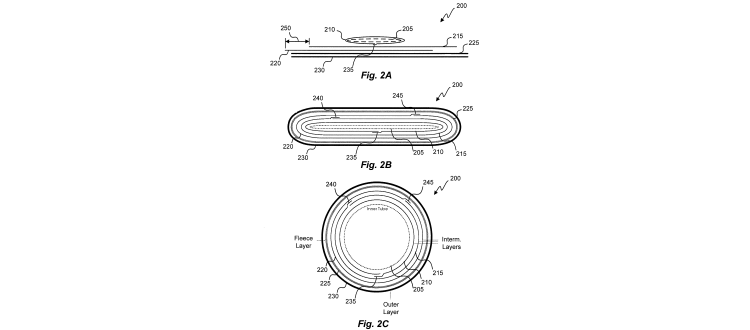

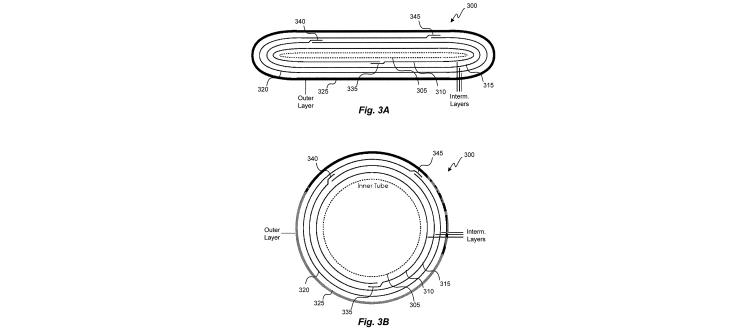

Liner Construction

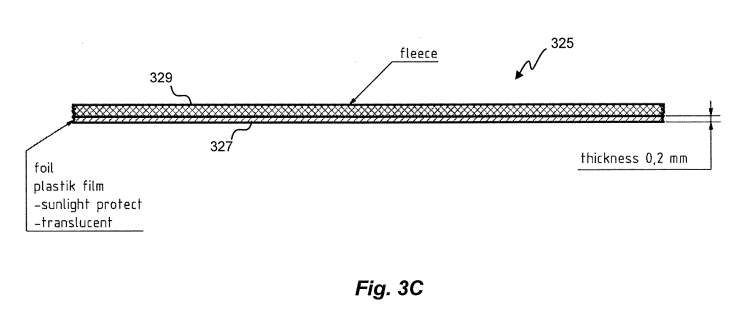

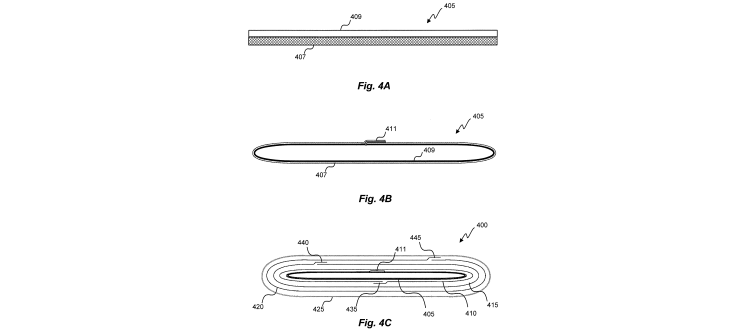

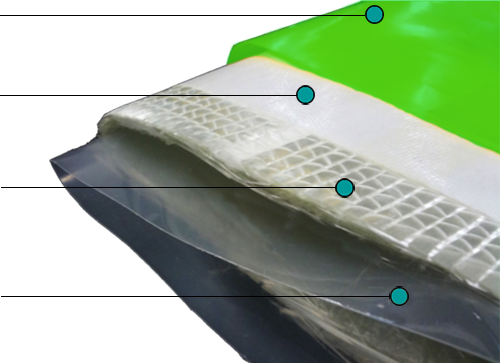

Patented Translucent UV Resistant Outerfoil

Polyester outer containment and protection foil

Multiple layers of high quality E-CR fiberglass. The fiberglass

layers are saturated with polyester or vinyl ester resins during manufacturing

Chemical and temperature resistant 7 layer

polyethylene/polyamineinner containment foil

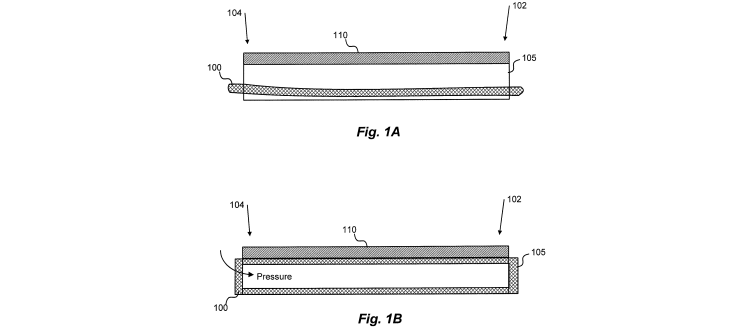

Cured Product

Outer foil remains in the pipe after curing

Resin “gelling” maintains consistent wall thickness during storage, shipping and installation

Clear inner foil is removed